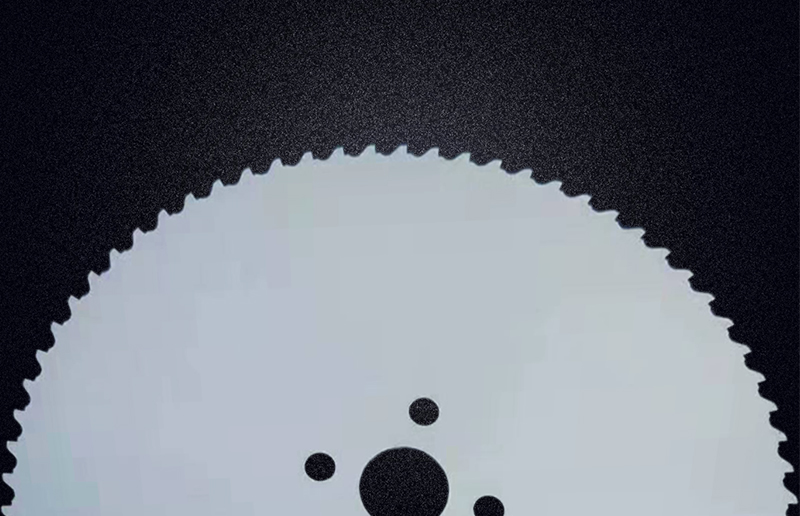

Cold saw substrate

We use Japanese sawing technology, import German and Japanese cold-rolled steel plates, and add precision substrate production equipment to manufacture high-precision saw blade substrates.

Main raw material: Japanese steel SKS51.

Main specifications: 100-600mm diameter.

Main production equipment: laser machine, stress machine, quenching furnace, pressure furnace, precision grinder.

inquiry

Main raw material: Japanese steel SKS51.

Main specifications: 100-600mm diameter.

Main production equipment: laser machine, stress machine, quenching furnace, pressure furnace, precision grinder.

Diamond saw blade for fiber cement board

For fiber cement board, floor and wood processing.

Use German 75cr1 steel plate and import pcd composite sheet.

Rigorous production process control and strict inspection guarantee the quality of products.

It is a supporting product for power tools and can be used for various brands of power tools.

The life of PCD is 30 times longer than carbige saw blade .

inquiry

Use German 75cr1 steel plate and import pcd composite sheet.

Rigorous production process control and strict inspection guarantee the quality of products.

It is a supporting product for power tools and can be used for various brands of power tools.

The life of PCD is 30 times longer than carbige saw blade .

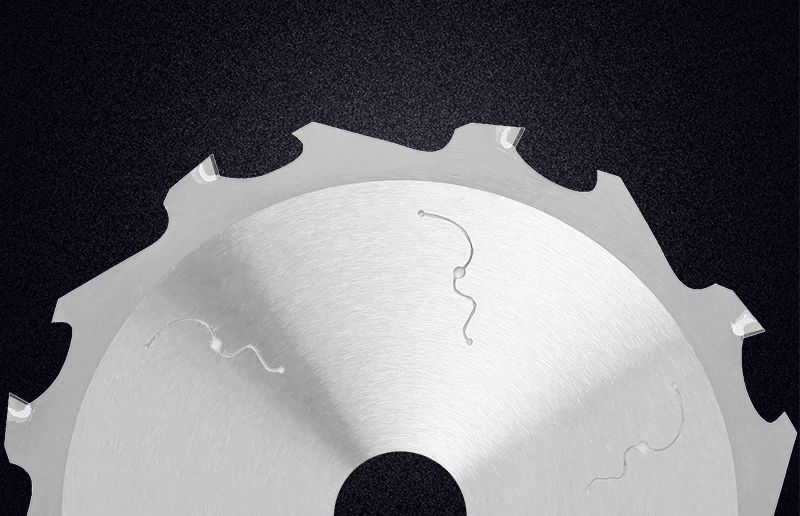

Diamond saw blade for laminated

Due to the high density of the laminate flooring and the high proportion of formaldehyde-based adhesives, the cutting life of cemented carbide saw blades is short.

The advent of diamond saw blades has increased lifespan by 30 to 50 times, making it our number one choice for laminate flooring.

Use German 75cr1 steel plate and import pcd composite sheet.

Rigorous production process control and strict inspection guarantee the quality of products.

inquiry

The advent of diamond saw blades has increased lifespan by 30 to 50 times, making it our number one choice for laminate flooring.

Use German 75cr1 steel plate and import pcd composite sheet.

Rigorous production process control and strict inspection guarantee the quality of products.

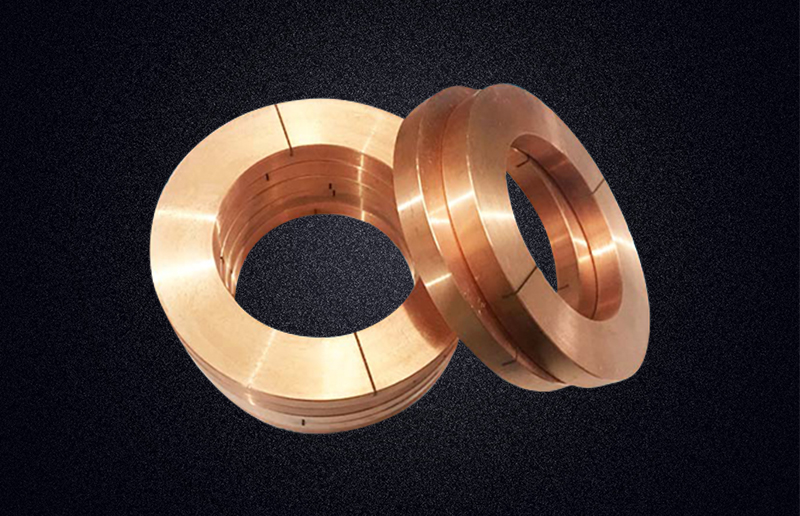

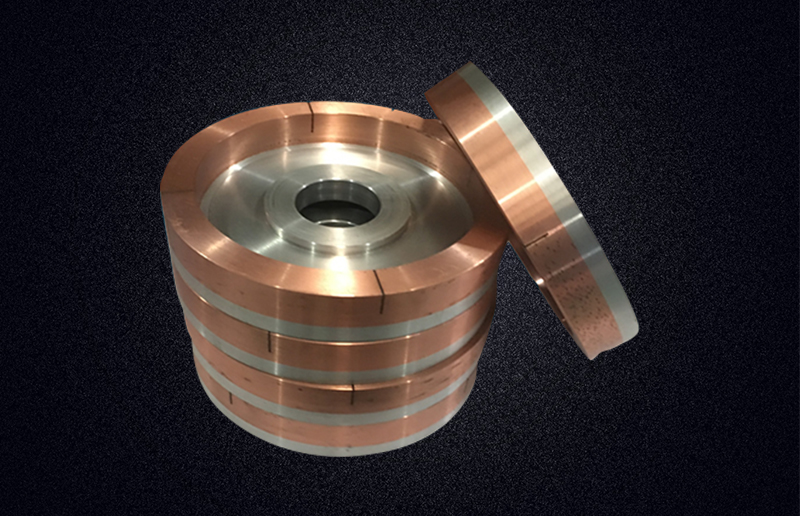

Diamond saw blade substrate

We use Japanese sawing technology, import German and Japanese cold-rolled steel plates, and add precision substrate production equipment to manufacture high-precision saw blade substrates for high-end diamond saw blade processing.

Main raw materials: Japanese steel SKS51, German steel 75Cr1.

Main specifications: diameter 50-1000mm, thickness 0.8-10mm.

Main production equipment: laser machine, stress machine, quenching furnace, pressure furnace, precision grinder.

inquiry

Main raw materials: Japanese steel SKS51, German steel 75Cr1.

Main specifications: diameter 50-1000mm, thickness 0.8-10mm.

Main production equipment: laser machine, stress machine, quenching furnace, pressure furnace, precision grinder.

Diamond saw blades for bamboo

Mainly for cutting bamboo products, such as bamboo flooring, chopsticks, etc., with long service life and good cutting effect.

Use German 75cr1 steel plate and import pcd composite sheet.

Rigorous production process control and strict inspection guarantee the quality of products.

The life of PCD is 30 times longer than carbige saw blade .

inquiry

Use German 75cr1 steel plate and import pcd composite sheet.

Rigorous production process control and strict inspection guarantee the quality of products.

The life of PCD is 30 times longer than carbige saw blade .

Diamond saw blades for non-ferrous metals

Suitable for cutting non-ferrous metal materials such as aluminum, copper, lead, etc.

Use German 75cr1 steel plate and import pcd composite sheet.

Rigorous production process control and strict inspection guarantee the quality of products.

The life of PCD is 30 times longer than carbige saw blade .

inquiry

Use German 75cr1 steel plate and import pcd composite sheet.

Rigorous production process control and strict inspection guarantee the quality of products.

The life of PCD is 30 times longer than carbige saw blade .

Diamond scribe saw

Uses: Pre-cutting of melamine veneer, paper veneer and other veneer based artificial boards.

Use German 75crI steel plate and import pcd composite sheet.

Rigorous production process control and strict inspection guarantee the quality of products.

Life is 30 times that of carbide saw blades.

inquiry

Use German 75crI steel plate and import pcd composite sheet.

Rigorous production process control and strict inspection guarantee the quality of products.

Life is 30 times that of carbide saw blades.

Electronic cutting saw blade

Uses: Cutting of veneer, veneer and other veneer based artificial boards.

Use German 75cr1 steel plate and import pcd composite sheet.

Rigorous production process control and strict inspection guarantee the quality of products.

The life of PCD is 30 times longer than carbige saw blade .

inquiry

Use German 75cr1 steel plate and import pcd composite sheet.

Rigorous production process control and strict inspection guarantee the quality of products.

The life of PCD is 30 times longer than carbige saw blade .

Panel sizing saw blade

For the processing of various wooden boards.

Use German 75cr1 steel plate and import pcd composite sheet.

Rigorous production process control and strict inspection guarantee the quality of products.

The life of PCD is 30 times longer than carbige saw blade .

inquiry

Use German 75cr1 steel plate and import pcd composite sheet.

Rigorous production process control and strict inspection guarantee the quality of products.

The life of PCD is 30 times longer than carbige saw blade .

PCB sizing saw blade

Electronic circuit board scribing.

Uses: V-groove cutting of glass fiber, carbon fiber, Kevlar fiber, polyethylene fiber circuit board material.

Use German 75cr1 steel plate and import pcd composite sheet.

Rigorous production process control and strict inspection guarantee the quality of products.

The life of PCD is 30 times longer than carbige saw blade .

inquiry

Uses: V-groove cutting of glass fiber, carbon fiber, Kevlar fiber, polyethylene fiber circuit board material.

Use German 75cr1 steel plate and import pcd composite sheet.

Rigorous production process control and strict inspection guarantee the quality of products.

The life of PCD is 30 times longer than carbige saw blade .

PCD Saw Blade EDM-S500D

· Side processing for diamond saw blade.

· Can use copper or graphite electrodes, automatic turning, automatic compensation.

· Using traditional hard alloy saw blade grinding platform combined with EDM technology, it is more professional, more accurate, more efficient, and easier to adjust than the tool platform.

· Menu-type product management design, just enter the product parameters into the menu system, the machine automatically adjusts the relevant parameters, and once entered, long-term storage, that is, call and work.

· Active fire identification and emergency handling system to ensure more safety.

· Independent research and development of EDM system, multi-level grading processing, can choose different discharge levels according to different customer types, in order to achieve the best choice of surface smoothness and efficiency of sawtooth.

· Coarse finish grinding is done at one time, no separate finishing is required.

inquiry

· Can use copper or graphite electrodes, automatic turning, automatic compensation.

· Using traditional hard alloy saw blade grinding platform combined with EDM technology, it is more professional, more accurate, more efficient, and easier to adjust than the tool platform.

· Menu-type product management design, just enter the product parameters into the menu system, the machine automatically adjusts the relevant parameters, and once entered, long-term storage, that is, call and work.

· Active fire identification and emergency handling system to ensure more safety.

· Independent research and development of EDM system, multi-level grading processing, can choose different discharge levels according to different customer types, in order to achieve the best choice of surface smoothness and efficiency of sawtooth.

· Coarse finish grinding is done at one time, no separate finishing is required.

PCD Saw Blade EDM-T500D

· Used for diamond saw blade top processing.

· Can use copper or graphite electrodes, automatic turning, automatic compensation.

· Using traditional hard alloy saw blade grinding platform combined with EDM technology, it is more professional, more accurate, more efficient, and easier to adjust than the tool platform.

· Menu-based product management design, just enter product parameters into the menu system, mechanically adjust related parameters automatically, and enter them once, save for a long time, and call and work

· Active fire identification and emergency handling system to ensure more safety.

· Independent research and development of EDM system, multi-level grading processing, can choose different discharge levels according to different customer types, in order to achieve the best choice of surface smoothness and efficiency of sawtooth.

· Coarse finish grinding is done at one time, no separate finishing is required.

· Combination of various complex tooth shapes, such as ladder teeth, sharp teeth, chamfered teeth, can be completed at one time.

inquiry

· Can use copper or graphite electrodes, automatic turning, automatic compensation.

· Using traditional hard alloy saw blade grinding platform combined with EDM technology, it is more professional, more accurate, more efficient, and easier to adjust than the tool platform.

· Menu-based product management design, just enter product parameters into the menu system, mechanically adjust related parameters automatically, and enter them once, save for a long time, and call and work

· Active fire identification and emergency handling system to ensure more safety.

· Independent research and development of EDM system, multi-level grading processing, can choose different discharge levels according to different customer types, in order to achieve the best choice of surface smoothness and efficiency of sawtooth.

· Coarse finish grinding is done at one time, no separate finishing is required.

· Combination of various complex tooth shapes, such as ladder teeth, sharp teeth, chamfered teeth, can be completed at one time.

PCD Saw Blade EDM-S1000

· Side processing for diamond saw blade.

· Can use copper or graphite electrodes, automatic turning, automatic compensation.

· Using traditional hard alloy saw blade grinding platform combined with EDM technology, it is more professional, more accurate, more efficient, and easier to adjust than the tool platform.

· Menu-based product management design, just enter product parameters into the menu system, mechanically adjust related parameters automatically, and enter them once, save for a long time, and call and work

· Active fire identification and emergency handling system to ensure more safety.

· Independent research and development of EDM system, multi-level grading processing, can choose different discharge levels according to different customer types, in order to achieve the best choice of surface smoothness and efficiency of sawtooth.

· Coarse finish grinding is done at one time, no separate finishing is required.

inquiry

· Can use copper or graphite electrodes, automatic turning, automatic compensation.

· Using traditional hard alloy saw blade grinding platform combined with EDM technology, it is more professional, more accurate, more efficient, and easier to adjust than the tool platform.

· Menu-based product management design, just enter product parameters into the menu system, mechanically adjust related parameters automatically, and enter them once, save for a long time, and call and work

· Active fire identification and emergency handling system to ensure more safety.

· Independent research and development of EDM system, multi-level grading processing, can choose different discharge levels according to different customer types, in order to achieve the best choice of surface smoothness and efficiency of sawtooth.

· Coarse finish grinding is done at one time, no separate finishing is required.

PCD Saw Blade EDM-T1000

· Used for diamond saw blade top processing

· Can use copper or graphite electrodes, automatic turning, automatic compensation.

· Using traditional hard alloy saw blade grinding platform combined with EDM technology, it is more professional, more accurate, more efficient, and easier to adjust than the tool platform.

· Menu-based product management design, just enter product parameters into the menu system, mechanically adjust related parameters automatically, and enter them once, save for a long time, and call and work

· Active fire identification and emergency handling system to ensure more safety.

· Independent research and development of EDM system, multi-level grading processing, can choose different discharge levels according to different customer types, in order to achieve the best choice of surface smoothness and efficiency of sawtooth.

· Coarse finish grinding is done at one time, no separate finishing is required.

· Combination of various complex tooth shapes, such as ladder teeth, sharp teeth, chamfered teeth, can be completed at one time.

inquiry

· Can use copper or graphite electrodes, automatic turning, automatic compensation.

· Using traditional hard alloy saw blade grinding platform combined with EDM technology, it is more professional, more accurate, more efficient, and easier to adjust than the tool platform.

· Menu-based product management design, just enter product parameters into the menu system, mechanically adjust related parameters automatically, and enter them once, save for a long time, and call and work

· Active fire identification and emergency handling system to ensure more safety.

· Independent research and development of EDM system, multi-level grading processing, can choose different discharge levels according to different customer types, in order to achieve the best choice of surface smoothness and efficiency of sawtooth.

· Coarse finish grinding is done at one time, no separate finishing is required.

· Combination of various complex tooth shapes, such as ladder teeth, sharp teeth, chamfered teeth, can be completed at one time.

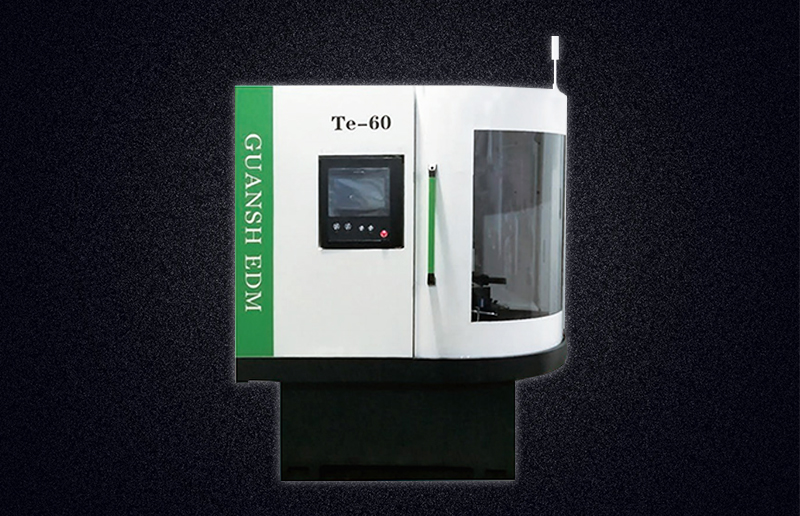

PCD Saw Blade EDM-Te60

· Used for machining the side and top of diamond saw blade.

· Can use copper or graphite electrodes, automatic turning, automatic compensation.

· Using traditional hard alloy saw blade grinding platform combined with EDM technology, it is more professional, more accurate, more efficient, and easier to adjust than the tool platform.

· Menu-based product management design, just enter product parameters into the menu system, mechanically adjust related parameters automatically, and enter them once, save for a long time, and call and work

· Active fire identification and emergency handling system to ensure more safety.

· Independent research and development of EDM system, multi-level grading processing, can choose different discharge levels according to different customer types, in order to achieve the best choice of surface smoothness and efficiency of sawtooth.

· Coarse finish grinding is done at one time, no separate finishing is required.

· Combination of various complex tooth shapes, such as ladder teeth, sharp teeth, chamfered teeth, can be completed at one time.

inquiry

· Can use copper or graphite electrodes, automatic turning, automatic compensation.

· Using traditional hard alloy saw blade grinding platform combined with EDM technology, it is more professional, more accurate, more efficient, and easier to adjust than the tool platform.

· Menu-based product management design, just enter product parameters into the menu system, mechanically adjust related parameters automatically, and enter them once, save for a long time, and call and work

· Active fire identification and emergency handling system to ensure more safety.

· Independent research and development of EDM system, multi-level grading processing, can choose different discharge levels according to different customer types, in order to achieve the best choice of surface smoothness and efficiency of sawtooth.

· Coarse finish grinding is done at one time, no separate finishing is required.

· Combination of various complex tooth shapes, such as ladder teeth, sharp teeth, chamfered teeth, can be completed at one time.

PCD Tool EDM-TC40

· Used for top surface machining of floor cutters.

· Using traditional hard alloy saw blade grinding platform, combined with EDM technology, it is more professional, more accurate, more efficient, and easier to adjust the processing of disc-shaped straight-edged tools than general-purpose machine tools.

· Menu-type product management design, just enter the product parameters into the menu system, the machine automatically adjusts the relevant parameters, and once entered, long-term storage, that is, call and work.

· Active fire identification and emergency handling system to ensure more safety.

· Independent research and development of EDM system, multi-level grading processing, can choose different discharge levels according to different customer types, in order to achieve the best choice of surface smoothness and efficiency of sawtooth.

· Coarse finish grinding is done at one time, no separate finishing is required.

· Combination of various complex tooth shapes, such as ladder teeth, sharp teeth, chamfered teeth, can be completed at one time.

inquiry

· Using traditional hard alloy saw blade grinding platform, combined with EDM technology, it is more professional, more accurate, more efficient, and easier to adjust the processing of disc-shaped straight-edged tools than general-purpose machine tools.

· Menu-type product management design, just enter the product parameters into the menu system, the machine automatically adjusts the relevant parameters, and once entered, long-term storage, that is, call and work.

· Active fire identification and emergency handling system to ensure more safety.

· Independent research and development of EDM system, multi-level grading processing, can choose different discharge levels according to different customer types, in order to achieve the best choice of surface smoothness and efficiency of sawtooth.

· Coarse finish grinding is done at one time, no separate finishing is required.

· Combination of various complex tooth shapes, such as ladder teeth, sharp teeth, chamfered teeth, can be completed at one time.

Side electrode

Posterior corner electrode

Milling cutter

Spiral milling cutter

Diamond wheel cutter

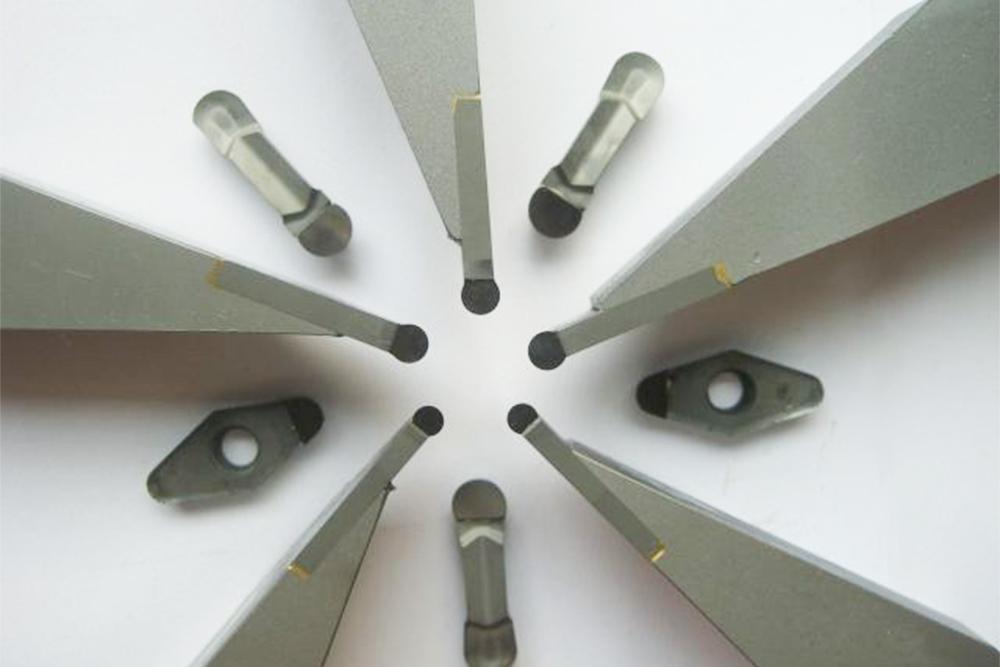

Diamond Machine Clip Blade

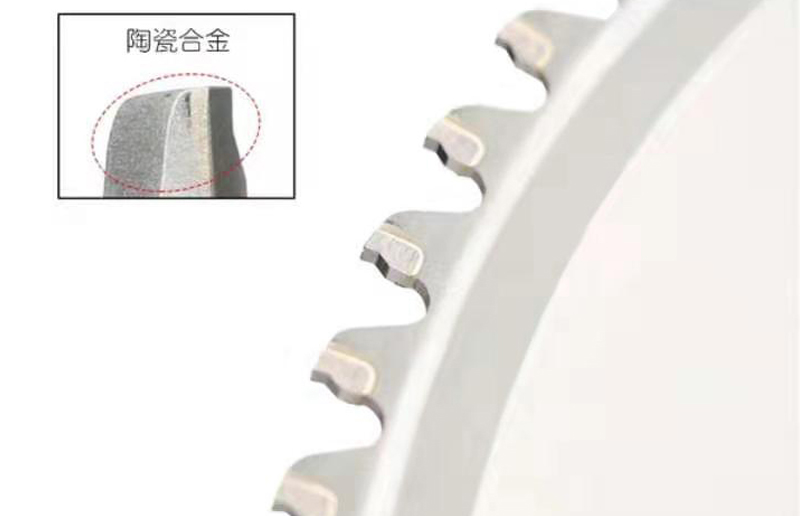

Cermet saw blade

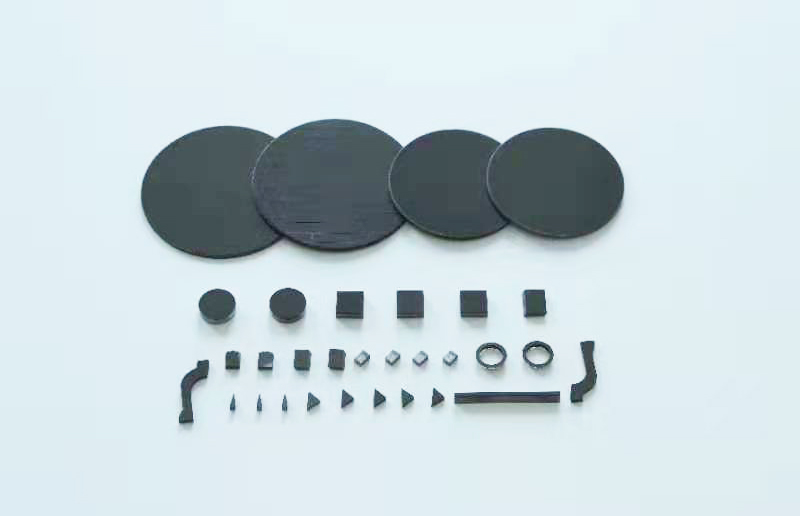

Polycrystalline diamond composite sheet

About Us

Hebei Guansh Automation Technology Co., Ltd. has professional mechanical design, saw blade design engineers, and experienced production technicians. Through rigorous selection of raw materials and strict process control, it guarantees the professionalism, high precision and product quality stability of the product; We have passed the ISO9001 international quality system certification, and currently have more than 70% market share of PCD saw blade discharge machine tools.

We provide customers with sincere service in a rigorous, realistic, and refined manner.

inquiry

We provide customers with sincere service in a rigorous, realistic, and refined manner.

The 20th China Shunde (Lunjiao) International Woodworking Machinery Expo

The 20th China Shunde (Lunjiao) International Woodworking Machinery Expo

[Starting time] December 6-9, 2019

inquiry

[Starting time] December 6-9, 2019

Vietnam Ho Chi Minh Woodworking Machinery and Furniture Fair VIETNAMWOOD

Vietnam Ho Chi Minh Woodworking Machinery and Furniture Fair VIETNAMWOOD

[Starting time] 2019.09.18 ~ 2019.09.21

inquiry

[Starting time] 2019.09.18 ~ 2019.09.21

2019 India International Woodworking and Furniture Accessories Exhibition DELHIWOOD

2019 India International Woodworking and Furniture Accessories Exhibition DELHIWOOD

2019 / India Furniture Panel Show / India Wood-based Panel Machinery Show / India Furniture Accessories Show / India Woodworking Machinery Show

[Exhibition time] March 13-16, 2019

inquiry

2019 / India Furniture Panel Show / India Wood-based Panel Machinery Show / India Furniture Accessories Show / India Woodworking Machinery Show

[Exhibition time] March 13-16, 2019

LIGNA 2019 Hannover Woodworking Machinery Exhibition

LIGNA 2019 Hannover Woodworking Machinery Exhibition

[Exhibition time]: May 27-31, 2019

inquiry

[Exhibition time]: May 27-31, 2019

contact us

Contact Information

- Puhui Street, Economic Development Zone, Fengnan District, Tangshan City, Hebei Province

- Tel: +86 0315-8907373

- After-sales service hotline:: +86 0315-8902827

- E-mail: info@guansh.net

- Fax: +86 0315-8161990

- whatsapp: +86 13180421118